Description

Archway packers represent a new innovation in packer design. The rubber sleeve is reinforced with “kevlar” strands giving each packer exceptional properties of expansion, strength and flexibility. The sleeve is further wrapped on the outside with several layers of high-elongation neoprene which is designed to resist erosion by contact with abrasive rock during positioning and working under pressure. The inner layer of the rubber “sandwich” consists of a tough nitrile rubber with a low permeability to compressed air or gas. All steel work is electroplated to prevent corrosion under usual operating conditions. The durability and expansion qualities of these units have already proved their superiority. One packer now has an expansion range which formerly would have required several units of different diameters to encompass.

Operation

All Archway packers come equipped with BSP end couplers. Adaptors can be supplied to attach the upper end of the stem to the drill string at point A. Sufficient length of inflation line is cut off and connected to the inlet port at point B. The ports are a push-fit design, allowing the inflation line to be connected in seconds. The packer is lowered into the borehole, ensuring that the bracketed end of the sleeve, point C, is uppermost in the borehole. Inflation is achieved using compressed air or a neutral gas (e.g. nitrogen). Water should not be used as the inflation medium as it may become impossible to deflate the packers fully once in¬flated in the borehole. During inflation the unit expands to a remarkable degree and reaches maximum diameter, beyond which it will not go due to the limitation imposed by the interlacing Kevlar strands. On deflation the packer reverts to its original diameter. The large expansion ratio makes extraction from the borehole very easy.

Important note

Care must be taken not to inflate the packer in an unrestrained position outside the borehole. For testing purposes the packer should always be placed inside a sealed steel tube which does not exceed the maximum diameter of the packer. Once inflated, the packer must not be moved inside the borehole as this may cause the sleeve to rupture.

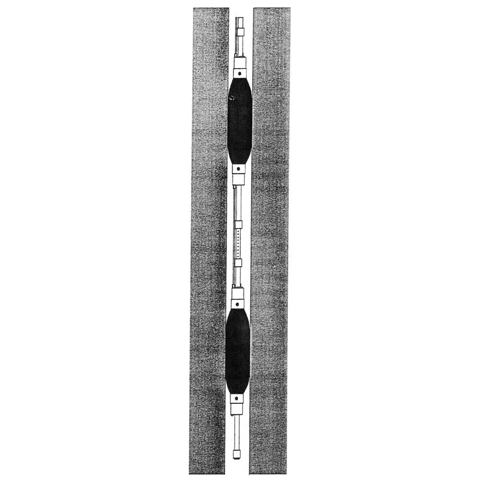

Double packers

Archway packers offer an additional flexibility in that single packer units can be simply coupled together to make a double packer, or a string of any number of packers in series. When a borehole zone is to be isolated, the units are joined in tandem with perforated pipe between the upper and lower packer units. The plug at the lower end of the upper packer sleeve is removed and an airline attached between the two packers. During inflation both packer units expand at the same time.

Ordering information

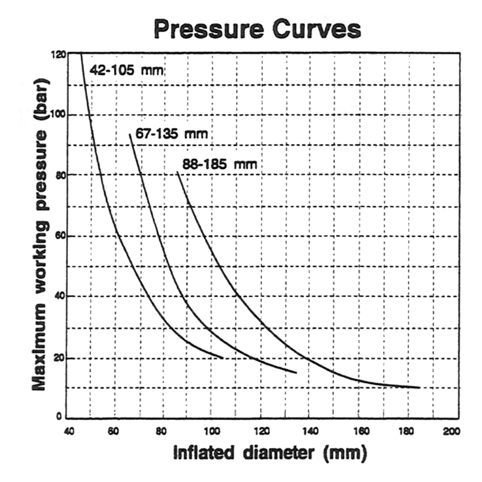

Archway packers are manufactured in five standard sizes, each with a different expansion range (see below). We recommend that you choose the largest available packer that fits into the borehole after allowing sufficient clearance for positioning and extraction. By leaving a sensible margin – so that a packer is not regularly inflated to its maximum diameter – the life of the rubber sleeve is much prolonged. It is also possible to inflate to much higher pressures when working well below the maximum expansion range, without jeopardising the life of the rubber (see Pressure Curves in the images above).

Standard length of the rubber sleeve is 1.0 m, but other lengths and non-standard diameters can be manufactured on request. We also supply inflation line in 30 m and 100 m coils, pressure gauges, and a range of valves and fittings to suit our packers.

[ultimatetables 17 /]

1 bar= 14.7 p.s.i.